Welcome To China Gwell Machinary Co., Ltd, Professional for Plastic

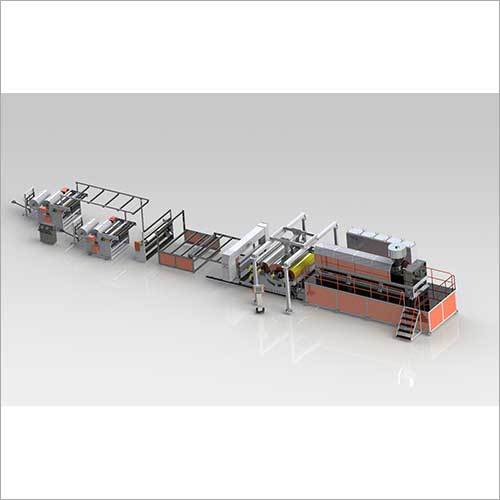

Eva Solar Film Extrusion Line

Product Details:

- Type GWS160

- Capacity 12 Ton/day

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Drive Type Other

- Screw Diameter 160 Millimeter (mm)

- Click to View more

Eva Solar Film Extrusion Line Price And Quantity

- 1 Unit

- 300000.00 - 400000.00 USD ($)/Unit

Eva Solar Film Extrusion Line Product Specifications

- 40 Tonne

- 400000 Watt (w)

- Yes

- 30*5*5 Millimeter (mm)

- Other

- Semi-Automatic

- PLC Control

- 12 Ton/day

- 1year

- 160 Millimeter (mm)

- GWS160

Eva Solar Film Extrusion Line Trade Information

- Telegraphic Transfer (T/T)

- 2000 Unit Per Year

- 100 Minutes

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

Eva Solar Film Extrusion Line

EVA solar film extrusion production line with low temperature process

EVA solar cell film is used for the encapsulation of solar cells. After laminating and curing, it is bonded and sealed, which plays a role in high light transmittance, preventing water vapor penetration, high and low temperature resistance and ultraviolet light resistance of the battery components, and ensures the stable and efficient use of the battery components. It is a kind of durable and reliable packaging material. Gwell machinery EVA solar film production line is in a monopolistic global leader.

Characteristics of Gwell EVA film production line:

(1) EVA single screw extruder is used for extrusion, and the barrel constant temperature circulating water cooling system solves the technical difficulties of EVA plasticizing and non-crosslinking.

(2) Double-sided embossing is adopted for the roller body, and technical difficulties of adhesive roller are solved.

(3) The cooling part adopts the cooling roller and the stress relief cold bed to make the film run smoothly and fully finalize the design, ensuring the shrinkage rate is less than 3%.

(4) The whole line adopts PLC automatic control to realize man-machine interface operation.

(5) The production line is equipped with online quality monitoring and control system to ensure the product qualification rate.

(6) Patented micro-tension winding machine, the line speed of the whole production line can reach 14m/min

EVA glass sandwich film, the products are widely used in:

Safety plate laminated glass, arc laminated glass, process laminated glass, bulletproof glass, discoloration laminated glass, conductive intelligent glass, solar cells and so on.

EVA hot melt adhesive film, embossed film, products are widely used in:

Sanitary products: medical operating suit, infant diaper membrane, women's sanitary towel bottom membrane, adult diaper membrane, pet pad membrane, disposable bed sheets, etc.

Daily necessities: umbrella, raincoat, suit coat, all kinds of table cloth, shower cap, shower curtain, apron, chair cover, etc.

Packing supplies: dust cover for computer appliances, soft packaging for cosmetics, shopping bags, gift bags, file bags, etc.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry