Welcome To China Gwell Machinary Co., Ltd, Professional for Plastic

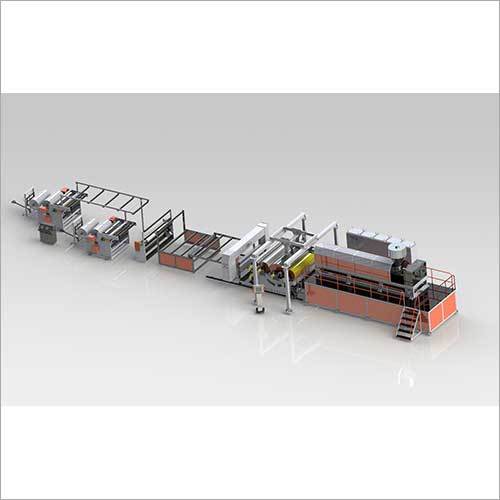

EVA solar hot melt adhesive plastic film sheet Extrusion machine

Product Details:

- Type GWS180

- Capacity 12 Tons/year

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Drive Type Direct

- Screw Diameter 180 Millimeter (mm)

- Click to View more

EVA solar hot melt adhesive plastic film sheet Extrusion machine Price And Quantity

- 1 Unit

EVA solar hot melt adhesive plastic film sheet Extrusion machine Product Specifications

- 12 Tons/year

- 40 Short Ton

- GWS180

- 180 Millimeter (mm)

- 1year

- Direct

- 30*5*7.5 Meter (m)

- PLC Control

- Yes

- Automatic

EVA solar hot melt adhesive plastic film sheet Extrusion machine Trade Information

- 2000 Unit Per Year

- 100 Days

Product Description

EVA packaging film production line of Gwell is in a monopolistic global leader position,and have about 90% market all over the world.We can provide service including both machine and formula. Gwell have provide complete solution for more than 10 years ,and our service is well received by our customers.

EVA solar cell adhesive film is used for solar cell encapsulation, after being laminated and cured, it is bonded and sealed to provide high light transmittance, prevent water vapor penetration, resistance to high and low temperatures, and ultraviolet light to ensure the stability and efficiency of the cell module. It is a durable and reliable packaging material.

The demand for photovoltaic film will more than double in the next five years. The continuous increase of module power driven by technological changes has led to the gradual dilution of the film consumption of single GW modules. However, the terminal installed capacity is growing at a high speed, and the demand for photovoltaic film will still maintain a high level of prosperity. It is estimated that the global demand for photovoltaic film will exceed 4 billion square meters in 2025. The CAGR for 2020-2025 is 20%.

The application scenarios of four typical photovoltaic films are gradually becoming clearer:

(1) Transparent and white EVA film: At present, single-glass modules usually use conventional transparent EVA film and white film for front and back encapsulation, and white EVA film has high reflectivity. As the bottom layer adhesive film, it can effectively improve the reflection of incident light between the cells and the transmitted light of the module, thereby increasing the efficiency of the module by 1W-3W.

(2) POE film: Due to the serious PID attenuation of double glass modules and N-type batteries, EVA resin can be replaced with POE resin with better water resistance, weather resistance and transmittance, and POE film was born.

(3) Multi-layer co-extruded POE film (EPE film, EVA/POE/EVA structure): Because POE resin is monopolized by a few foreign petrochemical companies, the price is expensive, and more bubbles will be generated when the module is laminated, resulting in The defective rate of polarizers and other films is increased, and the lamination time is prolonged.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Call Me Free

Call Me Free